Offering the Very Best in Strength and Flexibility

Utilising a specially engineered aluminium extrusion system, the solutions from Alloy Ute Canopies can deliver the very best in strength and flexibility. You will experience reduced weight and a further increase in your vehicle’s carrying capacity. Externally each alloy canopy is sheeted with three different gauges, with the lower section (everything below the tray deck) constructed of 3mm plate aluminium. This is important, as these areas are regularly subject to loose stones, sticks and logs.

The upper external parts (everything above the tray deck) are constructed of 2mm plate aluminium. When coupled with our extruded system, the panels are equivalent to or better than a 3mm construction, also helping to reduce weight. The internal parts are lined with a 1.6mm sheet, which allows a cavity for electrical wiring and offers the ability for insulation, as well as providing a clean, professional internal finish.

Frame Construction

Five specially engineered extrusions make up the construction of our canopies, each of which are physically connected to the other. We use a self-mating system, which eliminates welds from critical areas and allows each canopy to flex with your vehicle. When we do weld, we reinforce the section with a 150mm x 25mm planking section . The hinge is part of the extruded system, and at 25mm piano hinge with a 16mm stainless steel insert, is extremely strong.

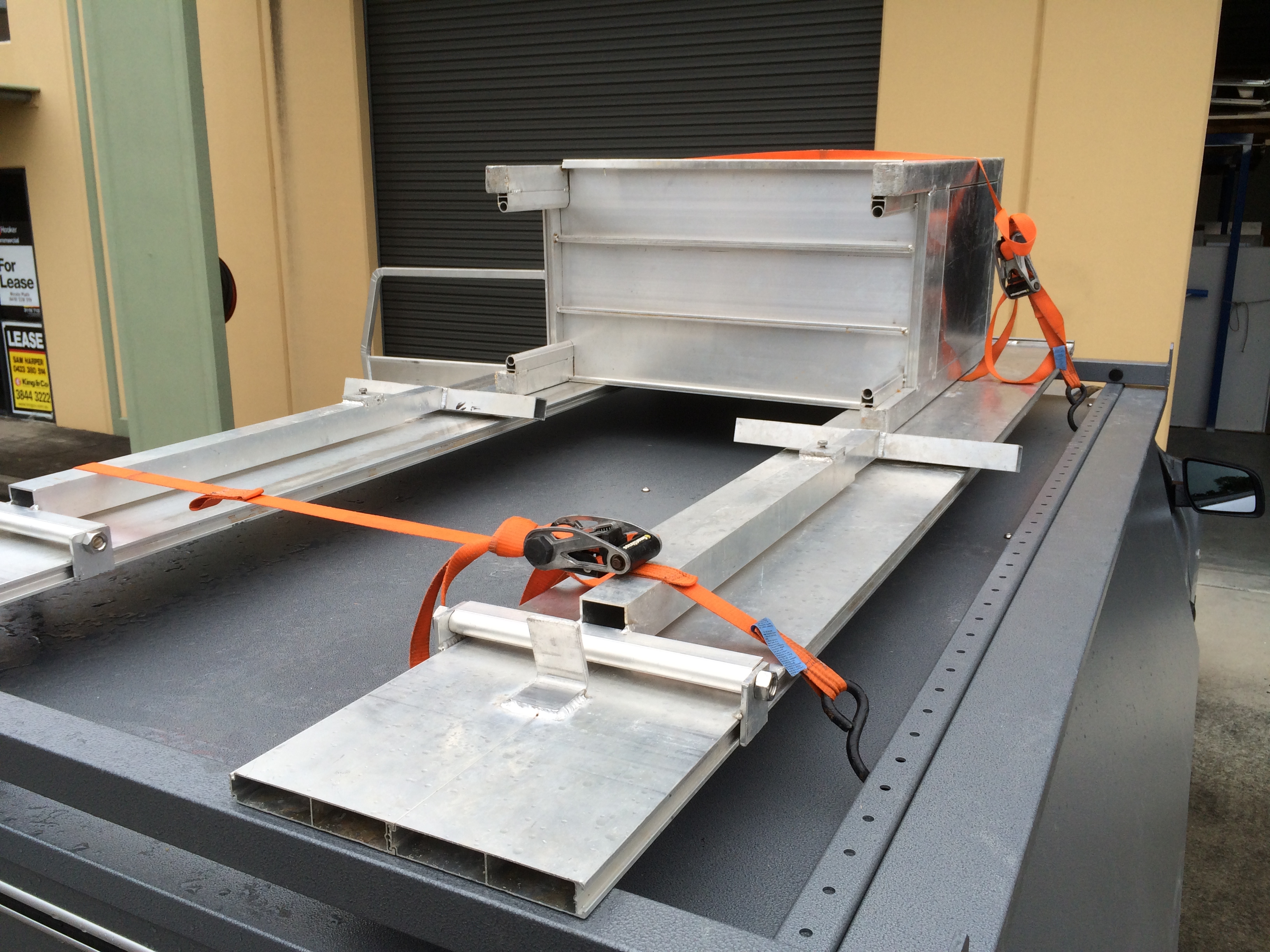

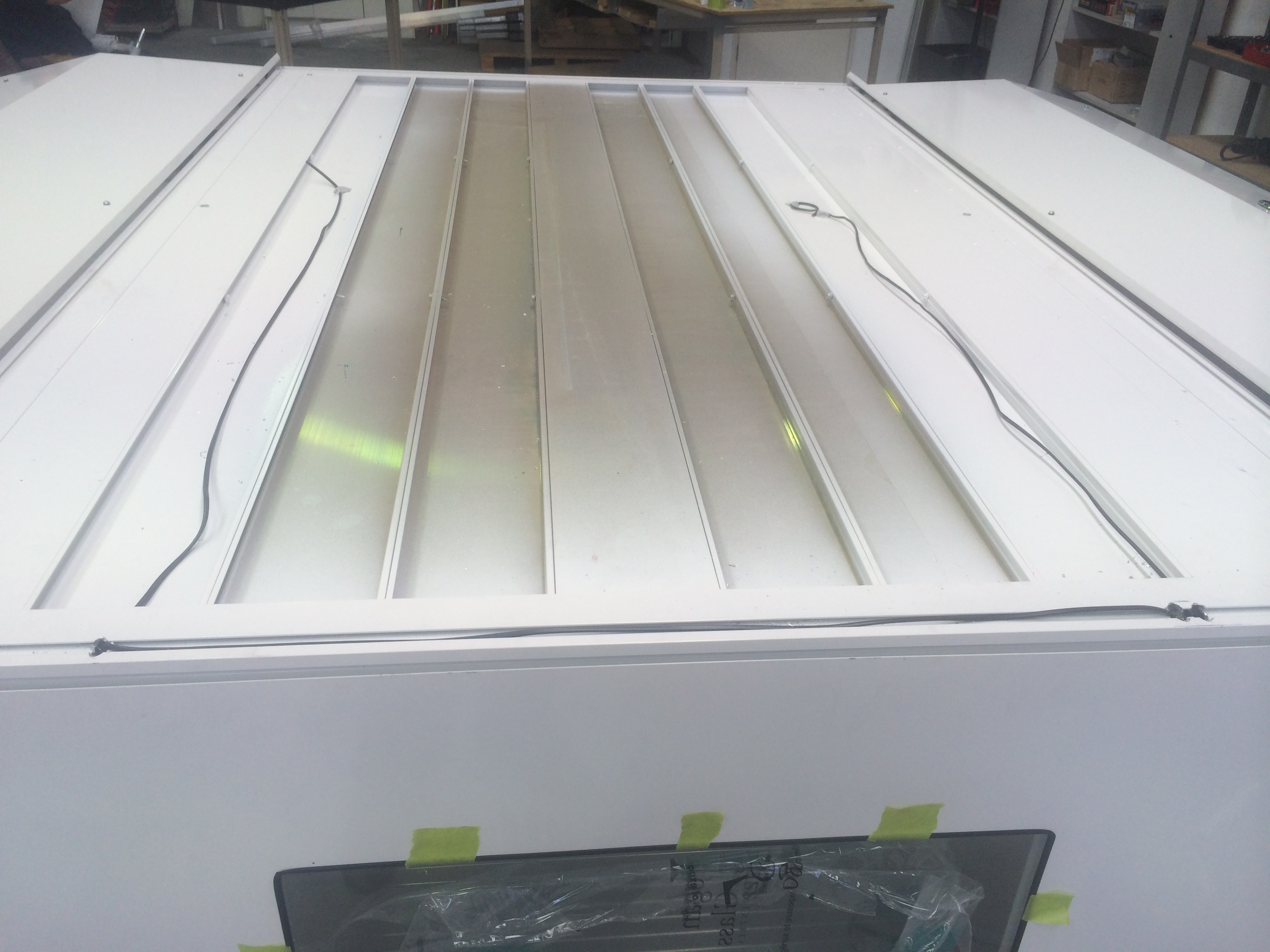

Roof Construction

The roof of each canopy is essentially a built-in roof rack. With durable construction, a load can be carried at any point of the roof, offering equal support. To facilitate the load carrying capacity, a rail runs down either side (front to back), with a 10mm tie point every 50mm.

A range of racks and boat loaders can be fitted to the already provided roof rack rails. Please note, while the roof can support 300 kg, it is a legal requirement that the load does not exceed 120kg.

Venting and Insulation

Recent testing over the summer period has seen an average of 7 degrees difference between the Cab of the vehicle and the Canopy Body. Thermometers have been placed in the center of both locations and readings taken over the middle of the day for 10 days strait.

Built into the roof and door system of the Canopy, the venting system ensures a controlled thermal environment.

Coupled with double skinned insulated panels, they are ideal for running a fridge or sensitive equipment. Front, rear and roof panels are foam filled to help insulate the canopy from heat. Optionally, the door panels can also be insulated.

The ventilation system provides for cargo such as fridges, freezers or sensitive electrical equipment. It also allows for live cargo such as Dogs. Dog or animal compartments can be allowed for in any of the Canopy Options.

Stainless Steel Tie Rails and Tray Deck Floor

The tray deck floor runs flat from one side to the other. Inserted on the outside edge of the floor running, front to back, is a stainless steel tie rail system.

This system is designed to be adjustable to suit each load.

Water and Dust Proofing

Our canopies offer maximum access, with doors on each side. Operating on gas struts, each door is open to the full length of the unit and is secured at three points. There is a further option of central locking.

Doors

Using the latest EPDM rubber and sponge seals, our canopies provide a dust and water free environment for your cargo.